Polyurea – As versatile as your demands.

Superior protection by PANADUR.

Polyurea systems by PANADUR are well-suited for seamless and jointless surfaces of compact and porous substrates. Thanks to its extraordinary properties, PANADUR polyurea solutions can be applied in the wind energy sector, in shipbuilding, in the automobile industry, in the construction sector and in structural steel work, and everywhere else where durability and longevity are essential.

With PANADUR there are simply no limits for unlocking your potential.

Polyurea – The future is now.

Polyurea is an extremely versatile coating material, which is currently the prime standard in more and more applications in industry and for everyday use. Experts agree that it is the coating system of the future: it is solvent-free,UV-resistance and it can be processed within seconds.

Polyurea is known for its excellent adhesive properties on plastics and metals. Aliphatic polyurea also offers 100 percent resistance to UV-rays, extreme elasticity, excellent abrasion resistance and the highest temperature stability.

Polyurea is the obvious choice for any coating project that must meet the highest standards of quality and durability.

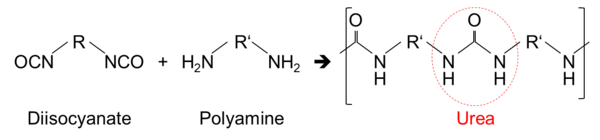

Polyurea is created from the reaction of polyvalent amines with equally polyvalent isocyanates. It is called polyurea because the polymer has a structural element that is very similar to urea. Structurally the three-dimensional polymer network with the characteristic structural unit of urea or polyurea is counted amongst the aminoplasts. The isocyanates used in the manufacturing of polyurea are either – with at least two or more isocyanate groups – monomer or polymer. Alternatively, prepolymers can be used and are created from isocyanates using the reaction with water. PANADUR polyurea, however, is very restrictive when it comes to the use of prepolymers: no solvents, no catalysts and no polyoles are used. PANADUR polyurea is free of chromate, tin and heavy metal and is 100 per cent made up of urea structures. Systems made from the two components of isocyanate and aliphatic amines mostly have a very fast reaction time due to the high nucleophilicity of the amines and are therefore predestined for machine processing in 2K spray systems. It is mostly aliphatic amines that are suitable for further processing by hand due to their slower reaction time. Polyurea differs structurally from the far better known polyurethane thanks to the use of an oxygen atom from nitrogen.

A step ahead of the competition. <br>With PANADUR.

We cater to your individual needs.

Aim for new opportunities with PANADUR polyurea systems.

- Individuality in form, design and colour

- Absence of release agents

- Resistance to corrosion

- Resistance to weathering and environmental influences

- High chemical resistance

Your solution – Without solvents.

PANADUR offers solvent-free polyurea and thus meets the latest European environmental regulations.

- Solvent-free system

- Contains lead- and chromate-free pigments

- Chemically resistant

- Energy-saving through drying at room temperature; no additional heating units are necessary